Sensible Value Chain through Digitalised Planning, Material handling and Circular Economy (SCARCE II)

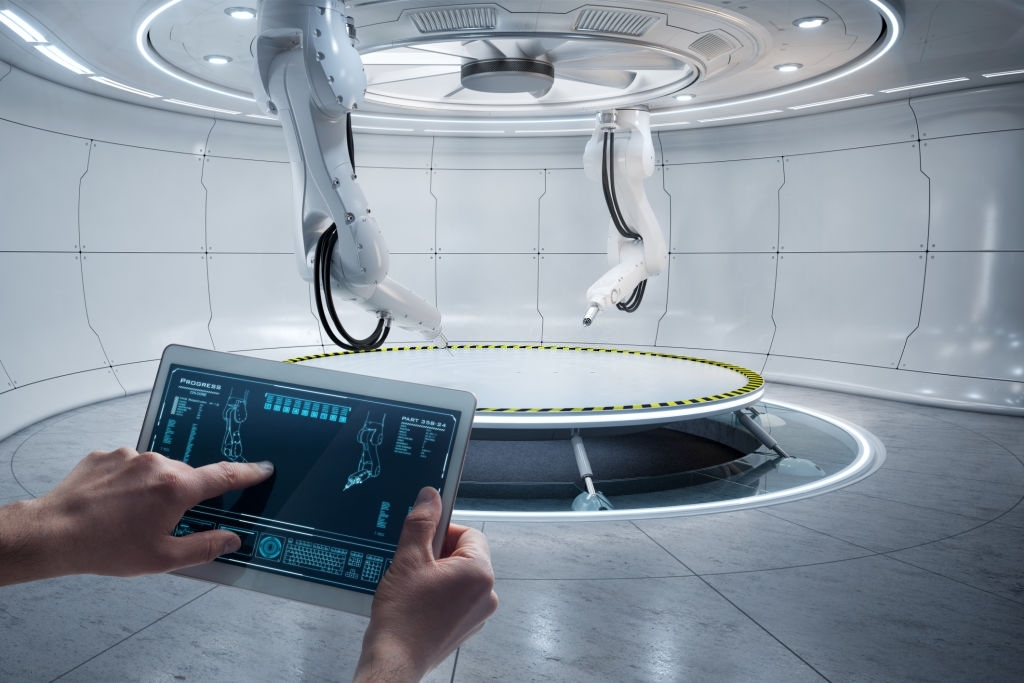

Today’s digital solutions for IoT platforms, automation solutions and transparent systems for displaying real-time data enable better planning and control in the value chain for SMEs.

Yet, the use of digital solutions is still mostly limited to monitoring of production processes, while the full potential remains unrealized. SCARCE II focuses on two subcontractors located in a value chain linked to Scania and Volvo.

In SCARCE I the following challenges were identified, to: i) categorize disruptions in productions to better plan production ii) adapt digital flows to introduce automation in material handling and iii) track packaging to increase efficiency and value linked to sustainability and ergonomics. In SCARCE II, a demonstrator will meet the challenges and show for SMEs and their associated value streams to increase efficiency, competitiveness and internal collaboration through digitalisation.

The demonstrator will be a cloud-based solution that connects three testbeds via pilots in the industry; Stena Industry Innovation lab, at Chalmers, RISE IVF lab in Mölndal and KTH’s testbed in Södertälje are connected with the help of technology suppliers Siemens, AFRY, Qbim and Virtual Manufacturing.

Project leader

Sandra Mattsson, RISE IVF

[email protected]

Participating organisations

→ RISE IVF

→ Chalmers University of Technology

→ Royal Institute of Technology

→Parker Hannifin AB

→ Bror Tonsjö AB

→ Qbim

→ Siemens

→ AFRY

→ EQpack

→Virtual Manufacturing