Flexible Additive Manufacturing of Micrometer/Millimeter Wave Components

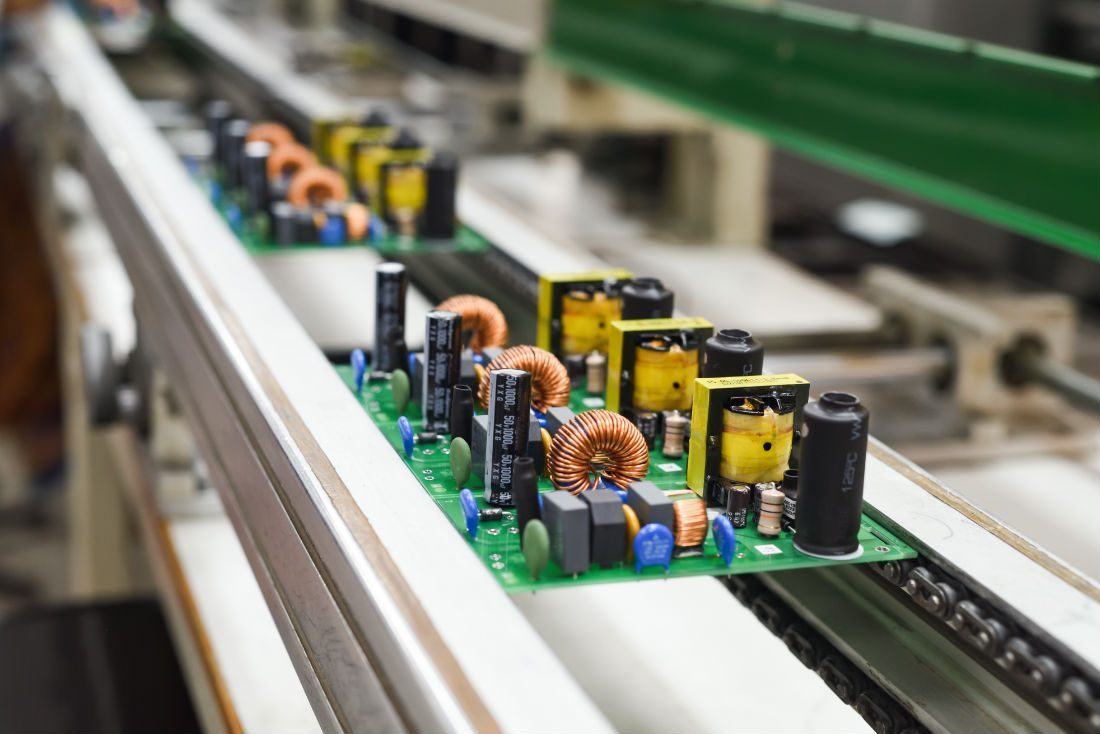

Next-generation of micrometer/millimeter wave components for future mobile communication would benefit significantly from further flexibility in product design.

Through additive manufacturing (AM), flexible production could be realized that would allow a future digital product platform for such flexible product design. The AM technology has so far not been addressed for this kind of application, but would if successful mean a significant breakthrough in product realization.

Owing to product specifications, mass customization could be combined with mass production with AM, which is not typical for AM. The basis for this potential future implementation is the combination of Cu-base materials solution and as near precision manufacture by AM as possible, where the powder-bed technologies laser powder bed fusion and binder jetting will be applied.

The project is a cooperative effort involving Ericsson as end-user and problem owner, Chalmers and RISE IVF as research providers and EOS and Digital Metal as core technology providers in AM. At project, the expected outcome is strengthened industrial ability in developing manufacturing to match future products through: A digital chain from product modeling to design for AM to product realization; proof-of-concept for applying AM to generate micrometer and millimeter wave components for future 5G systems; provision of Cu-base material solutions for laser powder bed fusion and binder jetting for intended future applications.

Project leader

Lars Nyborg

[email protected]

Participating partners

→ Chalmers University of Technology

→ RISE IVF AB

→ Ericsson AB

→ Digital Metal AB

→ EOS Oy