Organizing the Circular Economy Through A Network of LSAM Microfactories Recycling Ocean Plastics (OCEAN-LSAM)

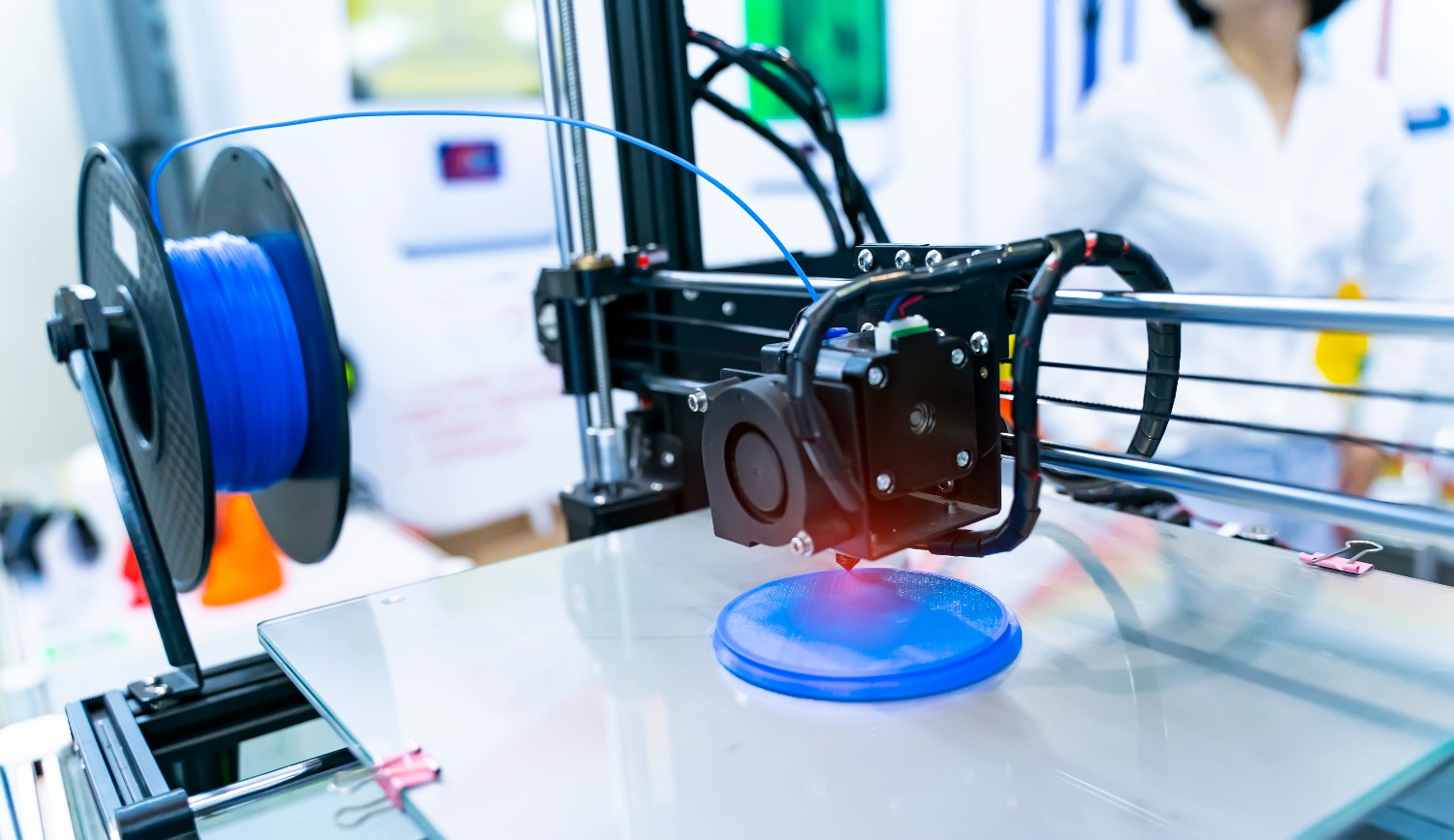

OCEAN-LSAM lays the foundation for tomorrow’s global network of circular economy microfactories producing large products designed by Swedish industry and produced from local recycled polymer waste streams through large-scale additive manufacturing (LSAM) equipment supplied by Swedish industry.

OCEAN-LSAM extends previous Vinnova/Produktion 2030 projects to conduct a Step 1 feasibility study demonstrating an integrated, optimized process for LSAM using recycled ocean polyamide waste (end-oflife fishing nets) before conducting a Step 2 full-scale project to demonstrate the circular economy microfactory concept using LSAM of local recycled ocean polymers across the entire supply chain. OCEAN-LSAM not only strengthens the competitiveness of the Swedish manufacturing industry, but it also enables Swedish industry to be the global frontrunner in the digital transformation to a truly circular economy model for tomorrow’s manufacturing.

While research shows the potential of using recycled polymers in LSAM, this project goes beyond by tackling the challenge of recycling ocean polymer waste to develop an integrated LSAM design and production process optimized for recycled ocean polymers. OCEAN-LSAM also extends previous research by developing a computational model to replace real-world tests, focusing on global stiffness, layer adhesion, and “hot-spot” identification (regions more prone to failure). Simulation results can improve current designs and enable the efficient investigation of new designs and products. In Step 2, OCEAN-LSAM takes a more holistic approach and explores the recycling of other ocean plastics while also creating a demonstrator of a circular economy microfactory involving the entire supply chain in which ocean polymer waste streams are transformed into LSAM-produced outputs through an integrated, optimized process. Thus, this project’s novelty is to extend previous LSAM efforts as an affordable, flexible solution for manufacturing medium to large scale components using recycled materials into the realm of using recycled ocean polymer wastes in addition to integrating this process within an optimized circular economy microfactory concept. In terms of impact, OCEAN-LSAM contributes to one Produktion2030 impact goal:

| Step 1 | Step 2 |

|---|---|

|

|

LSAM microfactories using recycled polymers enable companies to be both more agile and sustainable, compared to more traditional manufacturing, e.g., injection molding, as well as better prepare Swedish industry for future uncertainties, e.g., raw material shortages, pandemics, wars, natural disasters. OCEAN-LSAM also contributes to improving EU’s low plastic waste recycling rate of 32.5%1 and to decreasing the future use of virgin plastic, which is of dire importance as plastics production is expected to double within the next 20 years2. Thus, OCEAN-LSAM also contributes to four UN SDGs: SDG 9 Industry, Innovation, and Infrastructure, SDG 11 Sustainable Cities and Communities, SDG 12 Responsible Consumption and Production SDG 14 Life Below Water.

Project leader

Professor Robin Teigland, Chalmers

[email protected]

+46 31 772 6558

Participating organisations

→ Chalmers

→ RISE

→ Ocean Tech Hub LDA

→ Ekbacken Studios AB

→ Artex AB