Robust texture design for circular polymers – ROPY

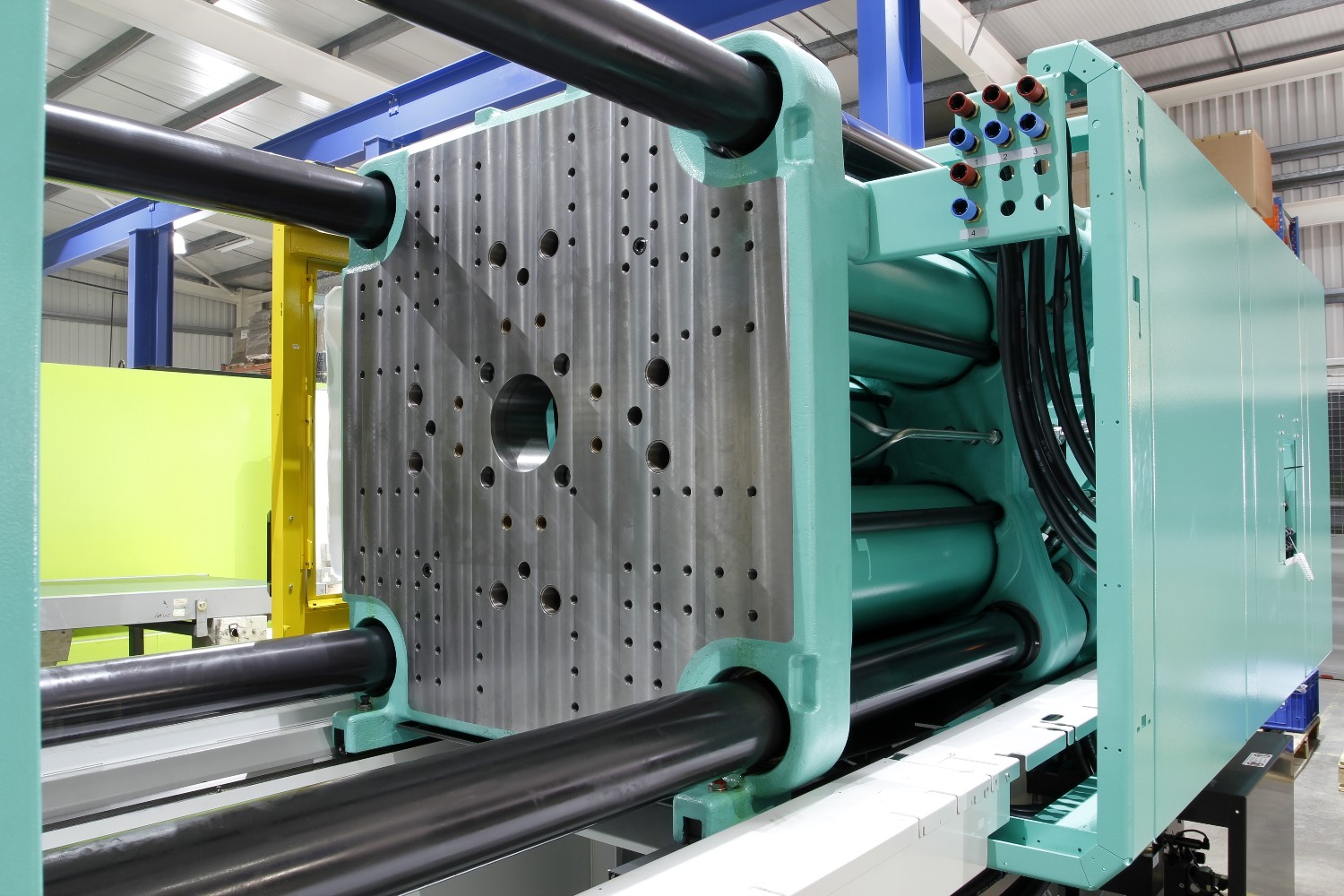

Interior automotive plastic components are often manufactured by injection moulding since this technique enable cost efficient manufacturing, large design freedom, and easy integration of functions. To achieve the intended appearance of the components they are normally given a texture, in addition to carefully selected colour and gloss properties. Moreover, the surface texture is closely related to the gloss, which also have a strong impact on the perceived colour of the component.

Replication quality of surface texture, from tool to component, depends on process conditions, polymer characteristics and nature of texture features. Prediction of the quality of replication can be made by combining process knowledge (polymers, processing conditions etc) with highly detailed knowledge on fidelity of replication of specific types of texture features. Robust surface textures can be designed that have a high probability to be replicated within specification with a variety of polymers, including material with large amount of recycled content.

The proposed project builds on a previous the FFI project. The new project makes use of the previously developed process knowledge and relation between material, process and surface feature replication. In the previous project, it was shown that it is possible to achieve the required replication quality with bio-based and recycled polymers and that it would be possible to predict deviations in quality texture using simulations. However, recycled polymers can have a larger variation in properties that has to be accounted for in the manufacturing process. The proposed project will develop methods and tools to increase the resilience to such variations to support circularity for polymers while taking end user perception of surface quality into account.

The project (step 1 and 2) will contribute to impact goal 3, increased use of renewable raw materials, by enabling the increased use of recycled material in polymer parts. Recycled polymers can have varying characteristics causing uncertainties regarding expected texture replication results and user perceived quality. Robust surface textures can be designed that have a high probability to be replicated within specification with a variety of polymers, including material with large amount of recycled content.

In addition, the project (step 1 and 2) will contribute to impact goal 1, increased service life of products and production systems, by enabling the design and manufacture of new components that match existing products. This will allow seamlessly integrating new components into existing complex products. The components can be spare parts, parts with new updated technology or that change the functionality of the product, thereby extending the service life of the product.

Projektledare

Johan Berglund, RISE

[email protected]

+46 10 228 47 04

Vi som samverkar

→ RISE

→ Chalmers

→ Halmstad University

→ Volvo Cars

→ Volvo Trucks